Lightweight aggregate plant

At present, the Chinese lightweight aggregate plant or LECA production line tends to adopt the industrial rotary kiln. The cylindrical main kiln is placed on the idler pulley with the horizontal dip angle of 3degree. Materials enter the kiln from the upper end and then fall to the bottom end of the kiln which is rotating. Meanwhile, at the kiln head, the high pressure draught fan sprays the cola powder or the natural gas to the kiln and then burns it completely.

Share With:

Introduction

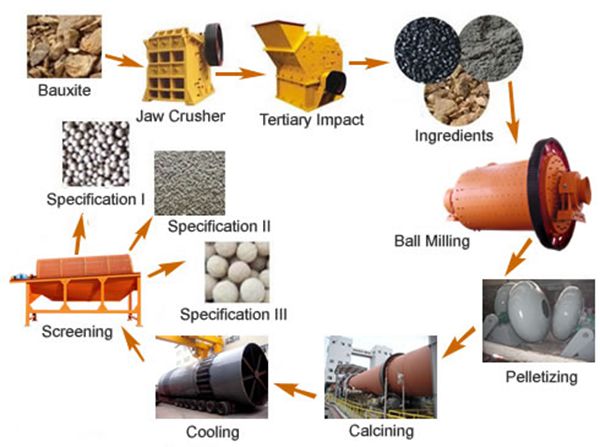

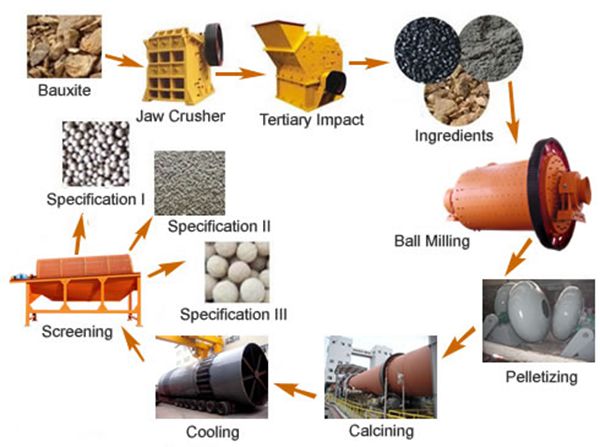

At present, the Chinese lightweight expanded clay aggregate production line tends to adopt the industrial rotary kiln. The cylindrical main kiln is placed on the idler pulley with the horizontal dip angle of 3degree. Materials enter the kiln from the upper end and then fall to the bottom end of the kiln which is rotating. Meanwhile, at the kiln head, the high pressure draught fan sprays the cola powder or the natural gas to the kiln and then burns it completely. The heat makes materials experience physical and chemical changes. They swell and then are cooled to finished ceramsite.

The ceramsite sand production line is made up of raw material storage bin, dust-settling compartment, induced draft fan, coal powder injection and control cabinet. The feeder set at the bottom of the raw material storage bin, and the revolution and the coal quantity of the kiln are both continuously viable in order to adjust the technical parameters and to realize the highest yield on the premise of good quality.

The ceramsite sand production line is made up of raw material storage bin, dust-settling compartment, induced draft fan, coal powder injection and control cabinet. The feeder set at the bottom of the raw material storage bin, and the revolution and the coal quantity of the kiln are both continuously viable in order to adjust the technical parameters and to realize the highest yield on the premise of good quality.

Send Message

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours..

WhatsApp: + 86 - 18903841927

WhatsApp: + 86 - 18903841927 Email: kldmachinery@gmail.com

Email: kldmachinery@gmail.com